THE OFFICIAL WEBSITE OF THE HAMMER’S SLAMMERS

THE CRUCIBLE RULES SYSTEM HANDBOOK

THE OFFICIAL WEBSITE OF THE HAMMER’S SLAMMERS

THE CRUCIBLE RULES SYSTEM HANDBOOK

Click pictures to enlarge

Click pictures to enlarge

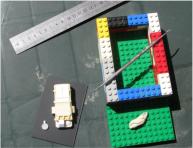

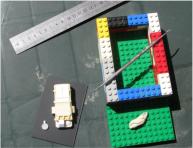

Building the vehicles

I stuck the hull and the separate hatch to a sheet of plastic card. Once it had dried, I sprayed it with

mould release to ensure that I would be able to get the master out of the mould! Finally I mixed and

poured RTV (room temperature vulcanising) rubber over it, mixed gently with the catalyst to avoid

too many air bubbles.

When you pour the rubber, pour it into a corner of the mould and allow it to flow around the master,

and use a toothpick to ensure there are no bubbles sticking to the master which will show up as

lumps in any castings. I allowed 24 hours drying time, then disassembled the lego wall and popped

the mould free. This gave me a one-part open mould; the most basic type, but perfect for what I

want.

Casting in resin is very simple. Dust talcum powder into the mould to ensure that it fills perfectly - the dry talc pulls the resin into the

smallest details. Mix resin and hardener in whatever proportions are recommended on the bottles (digital scales are really important

here) and pour gently into the mould. Poke around with a toothpick to loosen any air bubbles, then tap the mould. It takes about 20

minutes to bloom, set and cool and then you can pop it out.

A little cleaning up with a craft knife, a whizz over a sheet of sandpaper, and you have another hull. I spray mould release into the mould

after every casting; it is supposed to make the mould last longer. To equip all of the Apex Dragoons detachments from The Crucible I

need eighteen hulls; I cast around twentyfive (including a few miscast or given away) and the mould is starting to break up now. I might

cast a couple of hulls to turn into objectives or terrain, but that's just about it. Next page.

Building the vehicles

I stuck the hull and the separate hatch to a sheet of plastic card. Once it had dried, I sprayed it with

mould release to ensure that I would be able to get the master out of the mould! Finally I mixed and

poured RTV (room temperature vulcanising) rubber over it, mixed gently with the catalyst to avoid

too many air bubbles.

When you pour the rubber, pour it into a corner of the mould and allow it to flow around the master,

and use a toothpick to ensure there are no bubbles sticking to the master which will show up as

lumps in any castings. I allowed 24 hours drying time, then disassembled the lego wall and popped

the mould free. This gave me a one-part open mould; the most basic type, but perfect for what I

want.

Casting in resin is very simple. Dust talcum powder into the mould to ensure that it fills perfectly - the dry talc pulls the resin into the

smallest details. Mix resin and hardener in whatever proportions are recommended on the bottles (digital scales are really important

here) and pour gently into the mould. Poke around with a toothpick to loosen any air bubbles, then tap the mould. It takes about 20

minutes to bloom, set and cool and then you can pop it out.

A little cleaning up with a craft knife, a whizz over a sheet of sandpaper, and you have another hull. I spray mould release into the mould

after every casting; it is supposed to make the mould last longer. To equip all of the Apex Dragoons detachments from The Crucible I

need eighteen hulls; I cast around twentyfive (including a few miscast or given away) and the mould is starting to break up now. I might

cast a couple of hulls to turn into objectives or terrain, but that's just about it. Next page.

Early Apex Dragoons in 15mm - by Colin Hagreen

Early Apex Dragoons in 15mm - by Colin Hagreen

THE OFFICIAL WEBSITE OF THE HAMMER’S SLAMMERS

THE CRUCIBLE RULES SYSTEM HANDBOOK

THE OFFICIAL WEBSITE OF THE HAMMER’S SLAMMERS

THE CRUCIBLE RULES SYSTEM HANDBOOK

Click pictures to enlarge

Click pictures to enlarge

Building the vehicles

I stuck the hull and the separate hatch to a sheet of plastic card. Once it had dried, I sprayed it with

mould release to ensure that I would be able to get the master out of the mould! Finally I mixed and

poured RTV (room temperature vulcanising) rubber over it, mixed gently with the catalyst to avoid

too many air bubbles.

When you pour the rubber, pour it into a corner of the mould and allow it to flow around the master,

and use a toothpick to ensure there are no bubbles sticking to the master which will show up as

lumps in any castings. I allowed 24 hours drying time, then disassembled the lego wall and popped

the mould free. This gave me a one-part open mould; the most basic type, but perfect for what I

want.

Casting in resin is very simple. Dust talcum powder into the mould to ensure that it fills perfectly - the dry talc pulls the resin into the

smallest details. Mix resin and hardener in whatever proportions are recommended on the bottles (digital scales are really important

here) and pour gently into the mould. Poke around with a toothpick to loosen any air bubbles, then tap the mould. It takes about 20

minutes to bloom, set and cool and then you can pop it out.

A little cleaning up with a craft knife, a whizz over a sheet of sandpaper, and you have another hull. I spray mould release into the mould

after every casting; it is supposed to make the mould last longer. To equip all of the Apex Dragoons detachments from The Crucible I

need eighteen hulls; I cast around twentyfive (including a few miscast or given away) and the mould is starting to break up now. I might

cast a couple of hulls to turn into objectives or terrain, but that's just about it. Next page.

Building the vehicles

I stuck the hull and the separate hatch to a sheet of plastic card. Once it had dried, I sprayed it with

mould release to ensure that I would be able to get the master out of the mould! Finally I mixed and

poured RTV (room temperature vulcanising) rubber over it, mixed gently with the catalyst to avoid

too many air bubbles.

When you pour the rubber, pour it into a corner of the mould and allow it to flow around the master,

and use a toothpick to ensure there are no bubbles sticking to the master which will show up as

lumps in any castings. I allowed 24 hours drying time, then disassembled the lego wall and popped

the mould free. This gave me a one-part open mould; the most basic type, but perfect for what I

want.

Casting in resin is very simple. Dust talcum powder into the mould to ensure that it fills perfectly - the dry talc pulls the resin into the

smallest details. Mix resin and hardener in whatever proportions are recommended on the bottles (digital scales are really important

here) and pour gently into the mould. Poke around with a toothpick to loosen any air bubbles, then tap the mould. It takes about 20

minutes to bloom, set and cool and then you can pop it out.

A little cleaning up with a craft knife, a whizz over a sheet of sandpaper, and you have another hull. I spray mould release into the mould

after every casting; it is supposed to make the mould last longer. To equip all of the Apex Dragoons detachments from The Crucible I

need eighteen hulls; I cast around twentyfive (including a few miscast or given away) and the mould is starting to break up now. I might

cast a couple of hulls to turn into objectives or terrain, but that's just about it. Next page.

Early Apex Dragoons in 15mm - by Colin Hagreen

Early Apex Dragoons in 15mm - by Colin Hagreen